Cleaning challenges with the ultra-high vacuum components

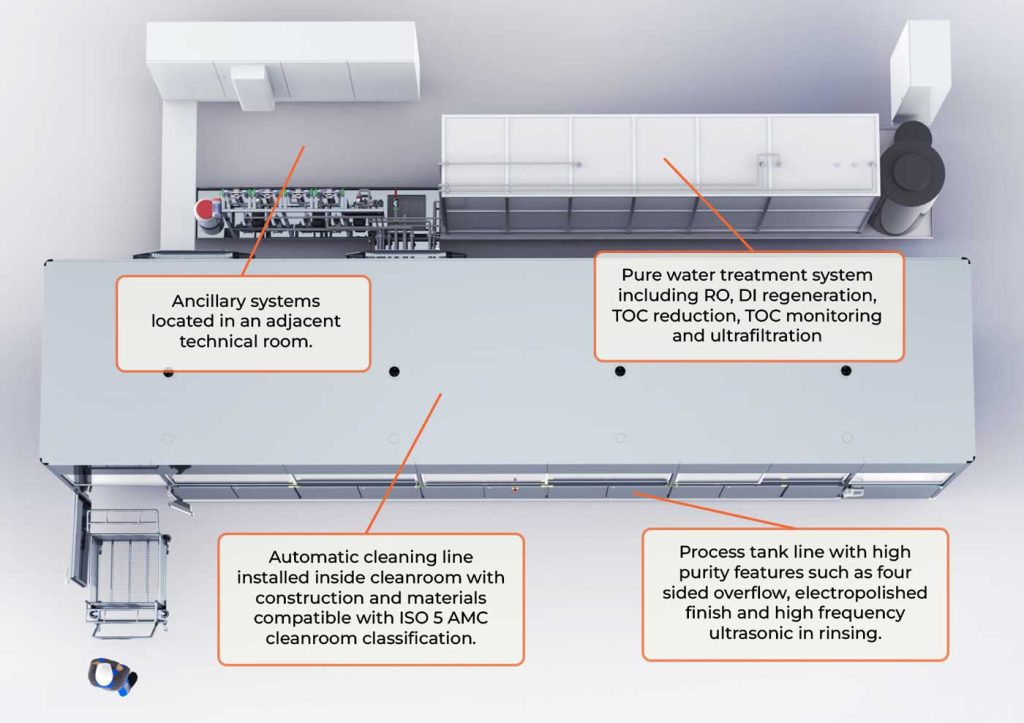

Cleanliness requirements for ultra-high vacuum components used in EUV optical systems are set very high in terms of residual particles, outgassing contamination and elemental impurities. Some of the structural components in these systems can be large and heavy, requiring big tank sizes and increased load capacities. Cleaning and consequent processing is conducted inside a cleanroom, which sets constraints on footprint and emissions caused by the cleaning line. All the requirements were successfully met thanks to a custom engineered FinnSonic Optima cleaning line.

Key benefits of choosing a FinnSonic solution

- Streamlined material flow and process integrity thanks to in-house final cleaning, integrated with consequent cleanroom processing.

- Automated processing ensures consistent cleaning results with reduced labor input.

- Data driven process optimization and quality improvements enabled by batch reporting and full event and process data logging.

- Fulfilment of individual requirements in terms of capacity, layout, installation access and detail design through custom engineered solution.

Treatment object

Components for EUV optical systems operating in ultra-high vacuum conditions. Materials: stainless steels, aluminium alloys, plastics.

Contamination

Particles, hydrocarbons, elemental impurities. Components come in pre-cleaned.

Compliance

- Field labeling according to NFPA79

- Cleanroom Class ISO 5 AMC

- Seismic anchoring

- CE

Cleanliness standards

- High purity cleaning (comparable to Grade II or I)

- Particles < 1µ

- Conductivity < 0.1 µS/cm

- Total Organic Carbon < 100 ppb

- Elemental impurities ppb

Capacity of the Optima line

- 800 x 800 x h600 mm basket internal dimensions

- 150 kg max component weight

System scope

- Automated ultrasonic cleaning line.

- Ultra-pure DI water supply and regeneration system.

Process features of the Optima line

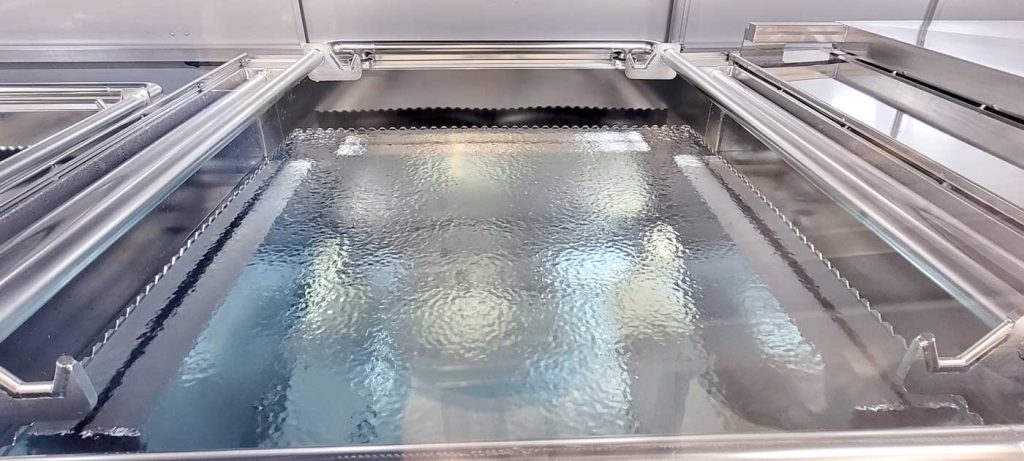

- Several ultrasonic wash and rinse stages utilizing 37 and 132 kHz ultrasonic frequencies.

- Drying stage with HEPA filtration.

- Basket transporter with ISO 5 certified linear motion systems.

- Full encapsulation with clean air distribution plenum ceiling and extraction ducts.

- Ultra-pure DI water supply and regeneration system including TOC reduction and monitoring and ultrafiltration.

- Intuitive control system with multiple HMI points, providing integrated control over the entire system.

- Batch reporting and full event and process data logging integrated with customer factory systems.